Biodegradable and compostable biopolymer

eco-friendly materialsBiobased and biodegradable

Derived from renewable resources and capable of breaking down naturallyNatural Biopolymers

Biologically renewable, biodegradable, biocompatible, non-toxic, bioadhesive material, biofuctional.Starch-based biopolymers

a natural, bio-based alternate to conventional petroleum-derived plastics such as polystyrene.Cellulose, (C₆H₁₀O₅)n:

This is the most abundant natural biopolymer, found in the cell walls of plants. It's used to make paper, textiles, and biodegradable plastics.Starch

Extracted from plants like corn and potatoes, starch can be processed into bioplastics used for packaging, bags, and disposable tableware.Polylactic Acid (PLA), (C3H4O2)n:

Derived from corn starch or sugar cane, PLA is a popular bioplastic used in disposable cutlery, transparent cups, and 3D printing.Biopolymers

Biodegradable

Biopolymers are biodegradable, which means they can break down into harmless natural substances over time. This makes them an environmentally friendly alternative to non-biodegradable materials, such as plastics

Biopolymer term comes from the Greek words “bio and polymer”, which represent nature and living organisms.

-

Biopolymers are natural alternatives to covalent-bonded artificial polymers.

-

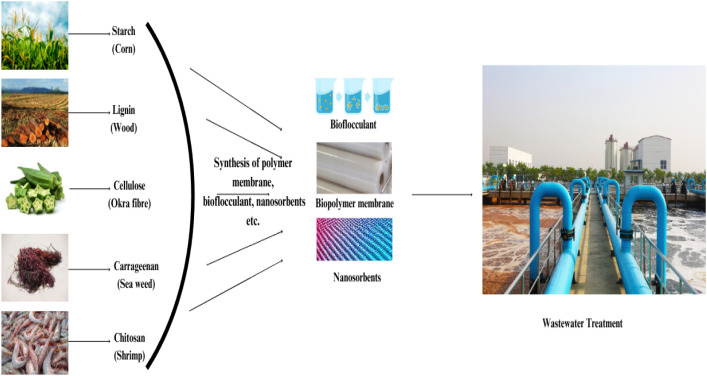

Biopolymer removes both organic and inorganic materials from wastewater.

-

Biopolymers store energy and produce electricity in various electronic devices.

-

Natural biopolymers including chitosan, starch, and cellulose reduce corrosion.

Packaging

In an effort to reduce plastic waste from packaging, biodegradable packaging is a particularly environmentally friendly application. Polyactic acid (PLA) and starch-based materials can be used to create packaging that decomposes naturally.

Bioplastics

Bioplastics are materials derived from natural or renewable resources, including plant, crustacean, and animal sources. Generally differentiated in the following three main groups: biobased and biodegradable; biobased and non-biodegradable; and non-biobased and biodegradable This means that not necessarily all kinds of biopolymers are both biobased and biodegradable.

Production Process:

The production of bioplastics generally involves the following steps:

-

- Feedstock Cultivation: The production of bioplastics prioritizes the use of waste streams and by-products from agricultural processes to minimize the impact on food resources. Plant biomass, such as agricultural residues, non-food crops, and other waste materials, are preferred sources. These materials provide starch, cellulose, hemicellulose, lignin, polyphenols, and triglycerides. For example, some bioplastics like PLA can be derived from agricultural waste products rather than crops grown specifically for human consumption.

- Extraction and Processing: The plant material is processed to extract sugars, starches, or other components, which are then fermented or chemically altered to create the precursors for the polymeric material.

- Polymerization: Through various chemical processes the extracted materials are transformed into bioplastics. For the case of PLA, this can be done by polycondensation or ring-opening polymerization.

- Shaping and Molding: Like conventional plastics, bioplastics can be molded into various shapes such as films, containers, fibers, and sheets.

Benefits

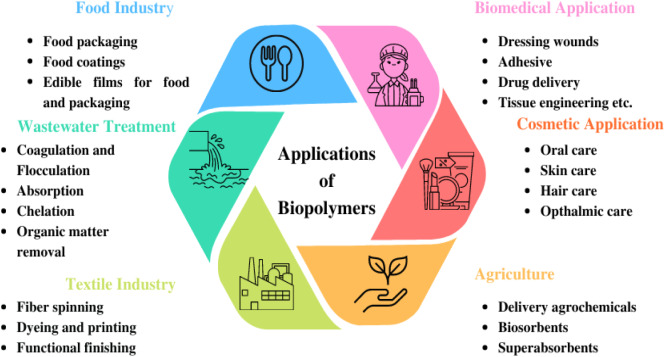

Renewable biological sources, including plants, animals, and microorganisms, are the source of biopolymers, they have attracted a lot of attention as a viable substitute for conventional synthetic polymers because of their sustainability, biodegradability, and biocompatibility. Due to their beneficial qualities, they have numerous significant uses in a variety of fields, including food packaging, bioengineering materials, wastewater treatment, anti-corrosive agents, and many more

Natural biopolymers like silk fibroin, chitosan, lignin, cellulose and others play a major role in all aspects of living. Along with other biotechnical materials, biopolymers are also used in the construction of buildings because they are biodegradable and biocompatible.

Plastic pollution vs. natural bio-polymer

Global primary plastic production is expected to reach 1.1 billion tons by 2050 if it keeps growing at the current rate. Comparatively, biopolymers are gaining more advantages in the aspect of social, economic and environment over synthetic polymers. Natural biopolymers are easily available and are of low cost with wide variety of uses and they are gaining popularity in current world [5,6]. They are used in many industries like textile industry, food packing, and for chemical use due to their individual and durable properties in nature